AcoustiFresh

FROZEN. BETTER THAN FRESH.

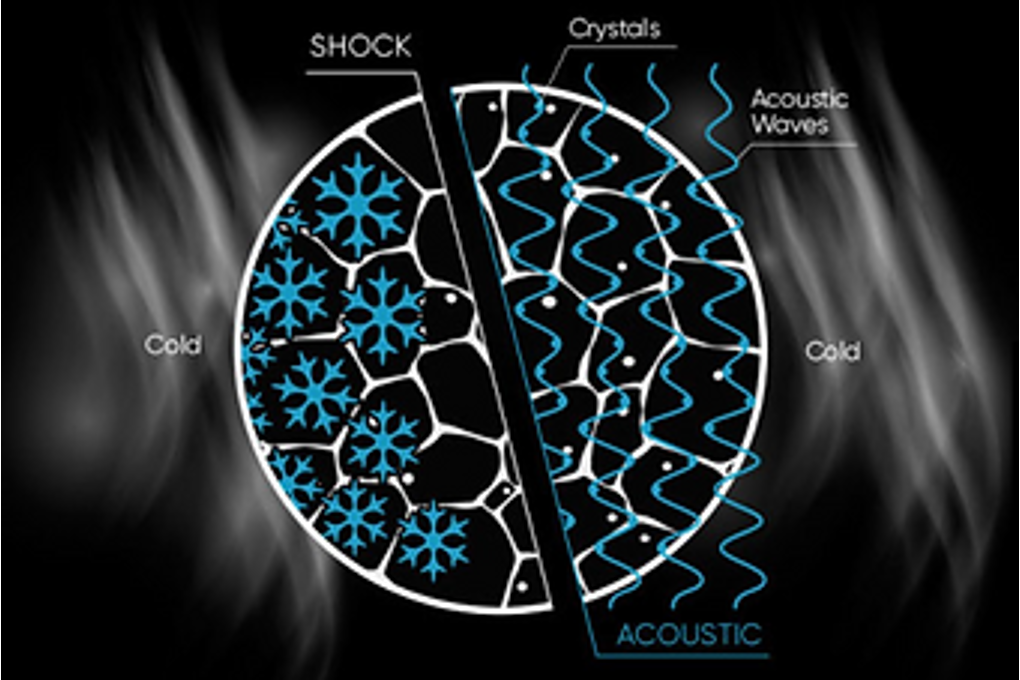

AcoustiFresh installs Acoustic Freezing Technology (AFT)—also known as Acoustic Extra Freezing—as a retrofit into existing freezer systems to better control ice crystal formation. The result is frozen product that holds texture, reduces moisture loss after thaw, and protects product integrity—without forcing a redesign of your line.

Better Texture,

Fresh-Like Quality

By controlling ice crystal formation during freezing, AFT helps preserve cellular structure—so texture, bite, and appearance hold up through freeze/thaw and downstream handling.

Higher Yield,

Reduced Drip Loss

Less cellular damage means less purge after thawing and better sellable yield—especially in products where moisture loss becomes margin loss.

Designed for Retrofit

into Existing Freezers

Enhance freezing performance without changing recipes, line speeds, or infrastructure.

What is Acoustic

Freezing Technology?

AFT is a freezing enhancement that uses controlled acoustic energy as part of the freezing process to influence ice crystal formation. Instead of only “making it colder,” the goal is to freeze in a way that better protects product structure—so frozen product performs more like fresh.

What Changes – And What Doesn’t

Changes: ice crystal behavior, freeze profile control, and post-thaw performance

Doesn’t Change: your recipes, upstream processing, packaging format, or plant utilities strategy (in most retrofit cases)